I’ve been spending a few evenings attacking some of the smaller, less interesting jobs. Some of these tasks have involved removing a few misguided ‘features’ that I tried out during the first build.

In preparation for removing the body I have had to dig out the expanded foam that I used to fill the sill voids. The idea was to save the sills members from rusting through by preventing road crud from attacking them. I now feel that the opposite would be true. The moisture would still find its way in but probably wouldn’t dry out so quickly which could hasten the corrosion process In any case its all got to come out so that the body can be removed. I won’t be repeating this experiment for the final build.

I did try to remove some of the body fixing screws and managed the grand total of just one, even using an impact driver! I will have to re-think this…

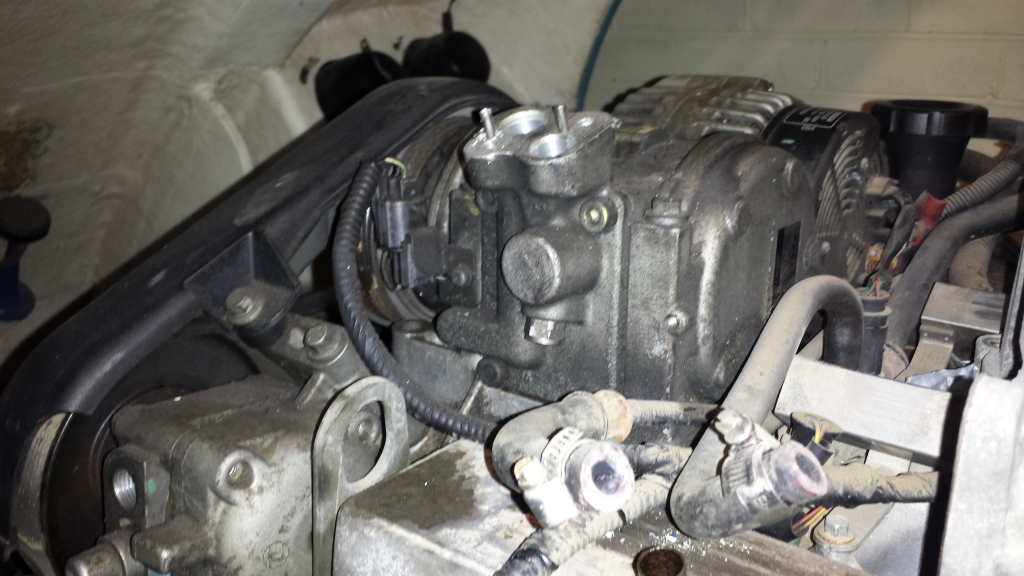

The bonnet now closes but the clearances are very tight on the back of the inlet manifold. I’m still deciding what to do about that. The engine is now resting correctly on its mountings too.

One thing that really will have to change is the sump. It’s far deeper on this engine than the old P6 V8. Ground clearance can only be 30mm, maybe less and that’s nowhere near enough for the Isle of Wight roads.

I picked up the Sierra differential, hubs and drive shafts for the IRS conversion. A lot of cleaning to do, but they seem to be in very good condition.

That’s all for now. Back with something more interesting next time.

Ian