I may have been unrealistically optimistic in my previous post from nearly a year and a half ago. Needless to say, but in all of that time I was unable to devote any hands-on effort to this neglected project.

That’s not to say that it was completely ignored, I’ve been buying more vital parts and planning my next steps.

Space to work

A lot of my spare time last year was spent fixing my tiny garage/workshop after the roof and a box gutter failed. That caused all sorts of side effect such as rusty engine ancillaries, tools, waterlogged walls and workbench. For some misguided reason I chose to fix it myself – ‘how hard can it be?’ Big mistake as it used up a lot of time I should have been giving to the Mantula. But it’s done now and the construction is quite epic in an over-engineered way.

After that was complete I did my best to reorganise and clean-up the small amount of available space. I’ve always wondered why the typical UK single garage is too narrow to even open the car doors! I’m also a firm believer that it’s much harder to keep a small workshop tidy than a larger one.

Some time ago the Mantula body was kept outside while the chassis was inside waiting for completion of the IRS upgrades. We had a new driveway laid, so the body had to come inside too. Now it sits on top of the chassis getting in the way and just serving as additional storage space, that has to change very soon – I have a lot to do…

Plan of action

Here’s what I hope to be doing between now and the end of May 2026, when I retire from the exciting world of aerospace technical publications software development!

Engine stuff

I’m currently fitting the ancillaries to the 4.6 V8 engine. That has started with the new water pump – the easy part. Next will be the reconfiguration of the serpentine belt and its tensioner. I need to change the location of the tensioner because it occupies the space needed for the steering shaft’s lower universal joint. It looks like there will be plenty of space where the power steering pump used to be. Of course this will mean modification of the existing alternator bracket and fabrication of a new bracket for the A/C compressor, tensioner and idler wheel. I’ll write this up in a separate post soon (I hope!).

My engine uses the Thor inlet manifold and I had originally planned to simply add two mechanical throttle bodies to each plenum. Again, I’ve changed my mind on how to achieve that and it will now involve twin Bosch 60 mm drive-by-wire throttle bodies! More about that later.

Wiring and a new VCU

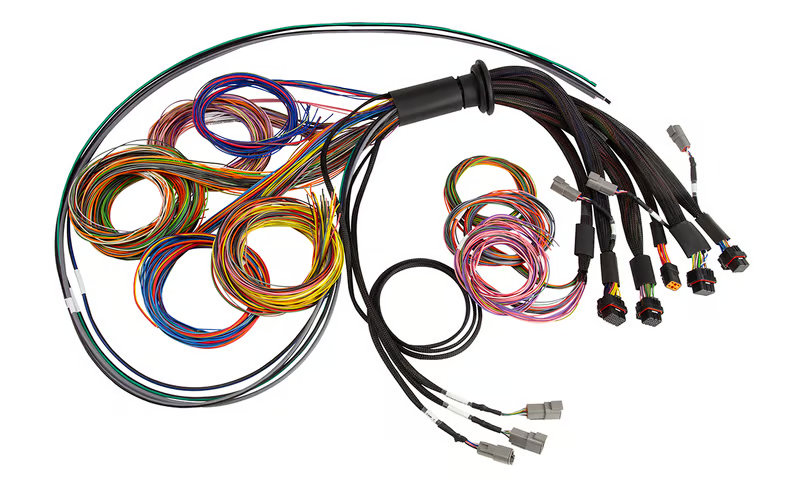

I’m ditching the original wiring loom and making my own using the Haltech R5 wiring harness. This is a universal wire harness pre-terminated to match the Haltech Nexus R5 Vehicle Control Unit

I was going to go for a full Mil-spec wiring loom, but couldn’t justify the time or cost. My chosen option uses high quality TXL wire following the Haltech wiring colour scheme.

The Haltech R5 Vehicle Control Unit is a very capable Engine Control Unit (ECU) and Power Distribution Module (PDM) combined into a single unit. The R5 will do away with the need for a fuse box or relays, everything is managed digitally. It has on board data logging and is fully programmable for engine tuning with more options than I may ever need. I should even be able to use it for traction and cruise control!

Switches and communication between devices will be over two CANBUS systems.

I’ll end this update there for today, but will follow-up with more news in a few days. Happy Christmas everyone!

One thought on “This time it’s for real”